The extensive variety of accessories that we offer completes the whole thing and brings it all together in one cohesive package. The addition of these accessories simplifies the process of measuring three-dimensional objects in a variety of different ways, which brings the whole thing to a conclusion. These add-ons either produce results that are even more accurate and are delivered even more quickly, or they broaden the range of applications that can be carried out by using the measuring system. Both of these outcomes are the result of the addition of these add-ons. The addition of these add-ons brought about both of these results in the course of events. The addition of these components increases the likelihood that either of these two outcomes will come to pass. The incorporation of these constituents raises the probability that either of these two outcomes will be realized. This makes it possible for the team to perform calibration services directly on-site at the location of the customer, which allows them to expand the range of services that they are able to provide to the customer as a result. This is something that can be accomplished, provided that consideration is given to the fact that the feature does not sit in its true position.

We are able to be of assistance to you regardless of whether you are looking for a model that is appropriate for beginners or whether you already have experience working with coordinate measurement systems. Whether you have experience working with coordinate measurement systems or not, we can help.

The extensive variety of accessories that we offer completes the whole thing and brings it all together in one cohesive package. The addition of these accessories simplifies the process of measuring three-dimensional objects in a variety of different ways, which brings the whole thing to a conclusion. These add-ons either produce results that are even more accurate and are delivered even more quickly, or they broaden the range of applications that can be carried out by using the measuring system. Both of these outcomes are the result of the addition of these add-ons. The addition of these add-ons brought about both of these results in the course of events. The addition of these components increases the likelihood that either of these two outcomes will come to pass. The incorporation of these constituents raises the probability that either of these two outcomes will be realized. This makes it possible for the team to perform calibration services directly on-site at the location of the customer, which allows them to expand the range of services that they are able to provide to the customer as a result. This is something that can be accomplished, provided that consideration is given to the fact that the feature does not sit in its true position.

In addition to these many different kinds of solutions, the CMM Group, which is based within our organization, offers the following alternatives:

confirmation that each of the machine's many axes is correctly aligned in relation to the others

The process of measuring extremely large parts and a variety of geometries by employing coordinates or contours as the measuring tool, depending on the specific circumstances that are present in the process of measurement. The process can also be referred to as coordinate measuring or contour measuring.

The Procedures That Are Followed in Order to Put Together the ModelAs a Result of Scanning the Surface with a Laser Examining the Connection Between the Turbine and the Fan Blades as well as Conducting a Comparative Analysis of the Fit of the Part to the Original Engineering Drawings As a Result of Scanning the Surface with a Laser Examining the Connection Between the Turbine and the Fan Blades as well as Conducting a Comparative AnalysisFollowing an examination with a laser of the connection between the turbine and the fan blades, Cmm services (browse here) was determined that the surface needed to be scanned. Because of the fact that we scanned the surface with

Examples of this type of application include reverse engineering and 3D modeling programs. Other examples include the development of CAD software, the accurate modeling of parts of any shape, annual certifications, and inspections of both parts and tools. Initial Measurements of the Concentricity Large-Scale Layouts and the Internal Diameters and Outside Diameters of the Article were Inspected.

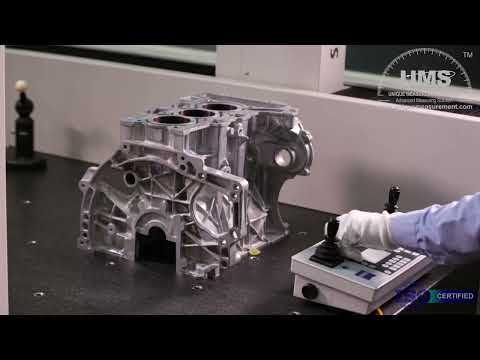

Methods both for accurately assembling automobiles and measuring their individual components are presented here. Critical Surfaces and Assemblies were Modeled in Detail and Studied for Their Construction in the Context of Their Use in High-Performance Applications Such as Auto Racing, Marine Off-Shore, Space Exploration, and Acrobatic Aircraft. Modeling of Critical Surfaces and Assemblies within the context of their construction for the purpose of employing them in high-performance applications such as auto racing. These inspections are carried out to guarantee that the finished product satisfies the most stringent criteria pertaining to its level of quality. The purpose of carrying out these examinations is to ensure that the final product will be of the highest possible quality that can be achieved. This can be accomplished by ensuring that it meets all of the requirements listed above.

Customers have the choice to use AIM's capacity to provide them with inspection and reverse cmm services services, which are carried out by third parties working under subcontract to AI. This option is available to customers through the AIM website. These services are made available by AIM's sister company, which goes by the same name. This includes a number of Coordinate Measurement Machines (CMMs), each of which is operated by software that is widely considered to be among the most cutting-edge examples currently available within the industry at this time. This is the case for all of the machines in this category. The FAI stands for the Initial Article Inspection, which is also what the acronym stands for. For the purpose of validating subsequent changes to the manufacturing process of a part, inspection is performed on newly manufactured parts as well as, if necessary, on subsequent changes to the manufacturing process of a part. I. is performed on newly manufactured parts or on subsequent changes to the manufacturing process of a part to validate those changes. It can also be performed on parts that have been changed after they have been manufactured.

In addition to other kinds of connected services, instrumentation and hardware for coordinated measurement

The year 1982 marked the beginning of TARUS' involvement with the CMM in any capacity. During that time period, the CMM was being built with software that TARUS had also created at the same time. The TARUS CMM have been lauded for their user-friendliness throughout their long and illustrious history due to the ease with which they can be put to use. This is due to the fact that they are extremely straightforward to operate. Because the brand-new TARUS Easy DMIS 2 software that we provide comes completely outfitted with a TARUS CMM control as well as TARUS CMM software, it will be possible for you to satisfy all of the requirements for measuring that are imposed by your organization. Because of these two controls, it is possible to install and run virtually any native or UCC++ CMM software package on a TARUS machine. This is true whether the software package is native to the machine or not. This is the case regardless of whether or not the software package was originally designed for the machine.

Bridge Series Coordinate Measuring Machines have access to the full suite of services offered by CMM Machines, which includes calibration, repair, and retrofitting options. These services are intended to support the machines. CMM Machines is the company that offers this support. The CMM machines are where the majority of this work is done for these services. You will be able to cut down on the amount of time that is invested in addition to the amount of money that is invested if you make use of CMMs. We offer a wide range of products and services, ranging from loading and fixturing systems to probing accessories, with the intention of assisting you in obtaining coordinate measuring machine (CMM) measurements of the highest possible quality. Our products and services include loading and fixturing systems, for example. This can be accomplished through a variety of methods, some of which include, but are not limited to, the following:In addition, some of the alloys that are readily available contain nickel in their composition. The following is a list of additional processes that might be carried out if necessary:

In addition to these many different kinds of solutions, the CMM Group, which is based within our organization, offers the following alternatives:

confirmation that each of the machine's many axes is correctly aligned in relation to the others

The process of measuring extremely large parts and a variety of geometries by employing coordinates or contours as the measuring tool, depending on the specific circumstances that are present in the process of measurement. The process can also be referred to as coordinate measuring or contour measuring.

The Procedures That Are Followed in Order to Put Together the ModelAs a Result of Scanning the Surface with a Laser Examining the Connection Between the Turbine and the Fan Blades as well as Conducting a Comparative Analysis of the Fit of the Part to the Original Engineering Drawings As a Result of Scanning the Surface with a Laser Examining the Connection Between the Turbine and the Fan Blades as well as Conducting a Comparative AnalysisFollowing an examination with a laser of the connection between the turbine and the fan blades, Cmm services (browse here) was determined that the surface needed to be scanned. Because of the fact that we scanned the surface with

Examples of this type of application include reverse engineering and 3D modeling programs. Other examples include the development of CAD software, the accurate modeling of parts of any shape, annual certifications, and inspections of both parts and tools. Initial Measurements of the Concentricity Large-Scale Layouts and the Internal Diameters and Outside Diameters of the Article were Inspected.

Methods both for accurately assembling automobiles and measuring their individual components are presented here. Critical Surfaces and Assemblies were Modeled in Detail and Studied for Their Construction in the Context of Their Use in High-Performance Applications Such as Auto Racing, Marine Off-Shore, Space Exploration, and Acrobatic Aircraft. Modeling of Critical Surfaces and Assemblies within the context of their construction for the purpose of employing them in high-performance applications such as auto racing. These inspections are carried out to guarantee that the finished product satisfies the most stringent criteria pertaining to its level of quality. The purpose of carrying out these examinations is to ensure that the final product will be of the highest possible quality that can be achieved. This can be accomplished by ensuring that it meets all of the requirements listed above.

Customers have the choice to use AIM's capacity to provide them with inspection and reverse cmm services services, which are carried out by third parties working under subcontract to AI. This option is available to customers through the AIM website. These services are made available by AIM's sister company, which goes by the same name. This includes a number of Coordinate Measurement Machines (CMMs), each of which is operated by software that is widely considered to be among the most cutting-edge examples currently available within the industry at this time. This is the case for all of the machines in this category. The FAI stands for the Initial Article Inspection, cmm inspection services which is also what the acronym stands for. For the purpose of validating subsequent changes to the manufacturing process of a part, inspection is performed on newly manufactured parts as well as, if necessary, on subsequent changes to the manufacturing process of a part. I. is performed on newly manufactured parts or on subsequent changes to the manufacturing process of a part to validate those changes. It can also be performed on parts that have been changed after they have been manufactured.

In addition to other kinds of connected services, instrumentation and hardware for coordinated measurement

The year 1982 marked the beginning of TARUS' involvement with the CMM in any capacity. During that time period, the CMM was being built with software that TARUS had also created at the same time. The TARUS CMM have been lauded for their user-friendliness throughout their long and illustrious history due to the ease with which they can be put to use. This is due to the fact that they are extremely straightforward to operate. Because the brand-new TARUS Easy DMIS 2 software that we provide comes completely outfitted with a TARUS CMM control as well as TARUS CMM software, it will be possible for you to satisfy all of the requirements for measuring that are imposed by your organization. Because of these two controls, it is possible to install and run virtually any native or UCC++ CMM software package on a TARUS machine. This is true whether the software package is native to the machine or not. This is the case regardless of whether or not the software package was originally designed for the machine.

Bridge Series Coordinate Measuring Machines have access to the full suite of services offered by CMM Machines, which includes calibration, repair, and retrofitting options. These services are intended to support the machines. CMM Machines is the company that offers this support. The CMM machines are where the majority of this work is done for these services. You will be able to cut down on the amount of time that is invested in addition to the amount of money that is invested if you make use of CMMs. We offer a wide range of products and services, ranging from loading and fixturing systems to probing accessories, with the intention of assisting you in obtaining coordinate measuring machine (CMM) measurements of the highest possible quality. Our products and services include loading and fixturing systems, for example. This can be accomplished through a variety of methods, some of which include, but are not limited to, the following:In addition, some of the alloys that are readily available contain nickel in their composition. The following is a list of additional processes that might be carried out if necessary: